rockwell hardness test procedure ppt|rockwell hardness test calculation : distributors Objectives To determine the Rockwell hardness number of various metal . Apostar no bicho atrasado na cabeça é uma das técnicas mais utilizadas para ganhar um bom prêmio no jogo do bicho. Pensando nisso, preparamos uma tabela com os bichos .

{plog:ftitle_list}

webAbout the match. Abha is going head to head with Al-Nassr starting on 12 Apr 2024 at 18:00 UTC . The match is a part of the Saudi Pro League. Abha played against Al-Nassr in 1 .

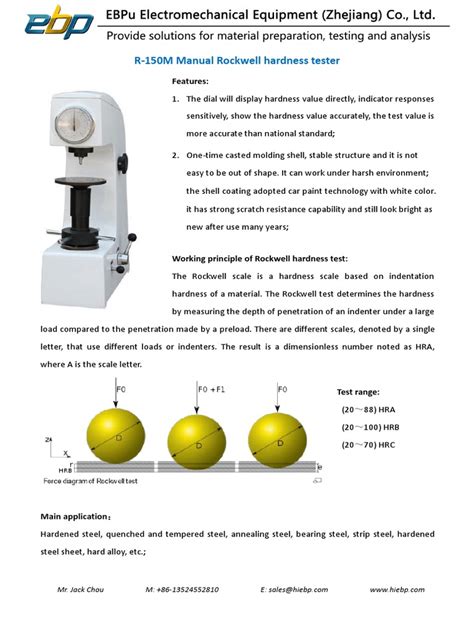

Rockwell hardness testing involves indenting a material with either a diamond or steel ball indenter under a minor preload and then a major load. The difference in indentation .Rockwell hardness testing measures the additional depth of a heavy load indenter .

Objectives To determine the Rockwell hardness number of various metal . Rockwell hardness testing measures the additional depth of a heavy load indenter beyond the depth of a previously applied light load. Both tests provide standardized hardness values and have advantages such as being .

Objectives To determine the Rockwell hardness number of various metal specimens. To develop an understanding of suitable scales for hardness test specimens. 3Scope* 1.1 These test methods cover the determination of the Rockwell hardness and the Rockwell superficial hardness of metallic materials, including test methods for the .

The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .Key Words: Hardness Testing, Brinell, Vickers, Rockwell, Mechanical Properties. Type of Module: PowerPoint presentation with lab or in-class demonstration depending on .

The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .

The Rockwell hardness test measures the hardness of a material by applying two loads to a diamond or steel ball indenter that is pressed into the surface of the material. The hardness number is determined using the formula HR = E - e, .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell . Objectives • To measure the hardness of the materials by Rockwell, Brinell and Vickers hardness test. • To become familiar with Combined Digital Hardness Tester. Introduction • Hardness is the resistance of metal to .hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . testing is covered by ASTM test method E 18. While all indentation hardness tests generally serve the same purpose, each one has definite advantages that make

1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .

spigen slim armor iphone 6 drop test

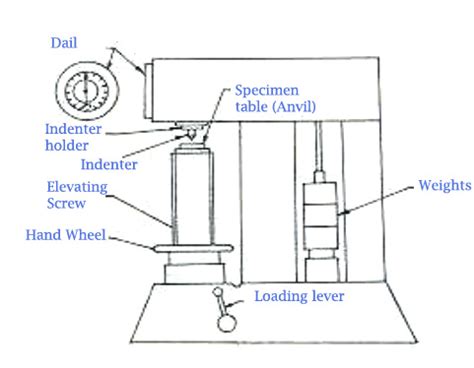

rockwell hardness testing machine diagram

Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool for5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial

3. Hardness is not necessarily an indication of strength , although for some materials such as steel, a harder steel is a stronger steel. Measure of a material’s ability to resist surface indentation or scratching A difficult property to describe in terms of first principles Þ value depends greatly on method of testing.Rockwell Test Procedure ASTM Standard E18. Select Scale - load and indentor depending on the scale ; Press the indenter into material - Diamond Indenter (Brale) - 1/16" ball - 1/8" ball; 30 . The PowerPoint PPT presentation: "Hardness Test" is the property of its rightful owner.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

Key Words: Hardness Testing, Brinell, Vickers, Rockwell, Mechanical Properties Type of Module: PowerPoint presentation with lab or in-class demonstration depending on characterization tools available Time required: 30-50 minutes with discussion . Module Procedure 1. Display each sample on a hard surface and discuss hardness and the varying .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured. Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. . ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard . ROCKWELL HARDNESS TESTING M FACTS Types of the Rockwell hardness Test Rockwell: The minor load is 10 kg, the major load is 60, 100, or 150 kg. Superficial Rockwell: The minor load is 3 kg and major loads are 15, 30, or 45 kg. In both tests, the indenter may be either a diamond cone or steel ball. The standard Rockwell test can not be used for .

method for rockwell hardness test for metallic material ( scales a-b-c-d-e-f-g-h-k 15n, 30n, 45n, 15t, 30t and 45t ) (third revision) ics 77.040.10 0 bis 2000 bureau of indian standards manak bhavan, 9 bahadur shah zafar marg new delhi 110002 october 2000 price group 9.Hardness Testing Hardness is the ability to withstand indentation or scratches. Hardness, which is a measure of a material’sresistance to localized plastic deformation (e.g., a small dent or a scratch). Qualitative Hardness Test Mohs Hardness Scale ranged from 1 on the soft end for talc to 10 for diamond.

8. Rockwell Hardness Testing The Rockwell hardness test method is a destructive type test It consists of indenting in the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under applied load and make a dent inside the specimen The movement of the indenter is measure by the dial gauge and .

II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation. 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. .

rockwell hardness testing instructions

Hardness Test Exp. #5 Eng. Ahmed S. Al-Afeefi Eng. Ibrahim aljaish. Objectives • To measure the hardness of the materials by Rockwell, Brinell and Vickers hardness test. • To become familiar with Combined Digital .Rockwell hardness test: Rockwell hardness test with the method of measuring pressure depth, hardness value through instructions direct reading, therefore, simple and convenient operation, easy to grasp, high efficiency, suitable for batch parts inspection; Rockwell hardness test method, can use diamond indenter andGuides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range . Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing.

E 4 Practices for Force Verification of Testing Machines3 E 140 Hardness Conversion Tables for Metals (Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell Superficial Hardness, Knoop Hard-ness, and Scleroscope Hardness)3 E 384 Test Method for Microindentation Hardness of Ma-terials3 3. TerminologyRockwell Indentation Hardness Test Apparatus GNEHM OM-150 Universal Hardness Tester Apparatus Diagram Set knob to correct load. Rockwell C test - set knob to 150kg . – A free PowerPoint PPT presentation (displayed as an HTML5 slide show) on PowerShow.com - id: 6c2da7-OWQzN . Tensile testing AC7101/3, Metallography AC7101/4, and Hardness .4.3 Verification of the indenter 4.3.1 Diamond cone indenter (scales A, C, D, N) To verify the reliable performance of the conical indenter in conformance with this part of ISO 6508, a directRockwell hardness test is one possible method to measure the hardness of plastics. This test method is named after Stanley P. Rockwell, who invented it in 1914. It is generally used for hard materials, like: polyamide (PA), polycarbonate (PC), polystyrene (PS), or; polyoxyethylene (POM).

1. HARDNESS TESTING METHOD - Hardness is the ability of material to withstand scratching, wear & abrasion or penetration by harder body. - The Metals Handbook defines Hardness as “Resistance of metal to plastic deformation, usually by indentation” It is the property of solid bodies, where the resistance is offered to plastic deformation and fracture, .What is hardness?Hardness Testing MethodsRockwell hardness test procedureAdvantagesA Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

Weld Consumable Calculation PPT Free Download For Training Welding Symbols PPT Free Download For Training Welding joint and symbols guide PDF of 96 pages . Rockwell Hardness Test: This method assesses the depth of indentation caused by a specific load on the material’s surface. It’s highly versatile and straightforward, making it widely .

spigen slim armor lg g2 drop test

O resultado da Quina concurso 6229 é publicado nesta página a partir das 20 horas de quarta-feira do dia 30 de agosto de 2023. Desejamos uma boa sorte a você apostador e .

rockwell hardness test procedure ppt|rockwell hardness test calculation